About Paper

Why Handmade Papers are Attractive For Me

Through the production of hand-made paper, natural elements seen in daily life are integrated into the media itself in another way.

Paper is not just a media as it adds a personal symbol and process of exploring the value of a new form and texture. The shape and color of plants can be sealed long enough to become a symbol of different stages and locations of records.

Creating hand-made paper has greatly shortened the distance between the works and the viewers. Compared with watercolors in the past, which mainly used visual senses, hand-made paper provides more textures and connections, enriching and extending the different senses through stimulus.

Diary of a Flower Thief - The Lives of Paper

A few months ago, flipping through a plant guidebook, I circled some specific endemic Taiwanese plants, as if selecting concubines, to collect.

During that time, I came up with a project where a space could showcase thousands, or even tens of thousands, of different papers and the lives of plants. I was certain it would be an unprecedented spectacle.

With my paper-making tools in tow, I stuffed the back of my car full. The plan was to travel from the eastern part of Taiwan all the way to Hualien, collecting plants along the way to make paper. The biggest challenge at that time was preserving the freshness and colors of the plants. Since I could only make paper in hotels, I was constantly racing against the plants' lifespans. The most difficult ones were some alpine plants, as the lowland temperatures were their biggest threat.

What materials can be added to handmade papers?

Main Material (Pulp)

Almost any paper can be used, except for ink-printed and any adhesive-bound papers. Ink-printed paper may make the pulp dirty or result in the paper not becoming as white. A typical example is newspapers (though they can produce good effects, they will have an ink odor). Adhesive-bound papers have waterproof properties that require special treatment to soften them, making them unsuitable for making paper.

Suitable for Reuse:

Cardboard, Cloud Paper, Watercolor Paper, Photocopy Paper, Drawing Paper, Thick Cardboard…

Additional Material (Pulp)

Material Mix:

If different pulps are mixed, the texture after drying will be like opening a blind box.

Color Variation:

Apart from texture variation, mixing different pulps also results in different colors.

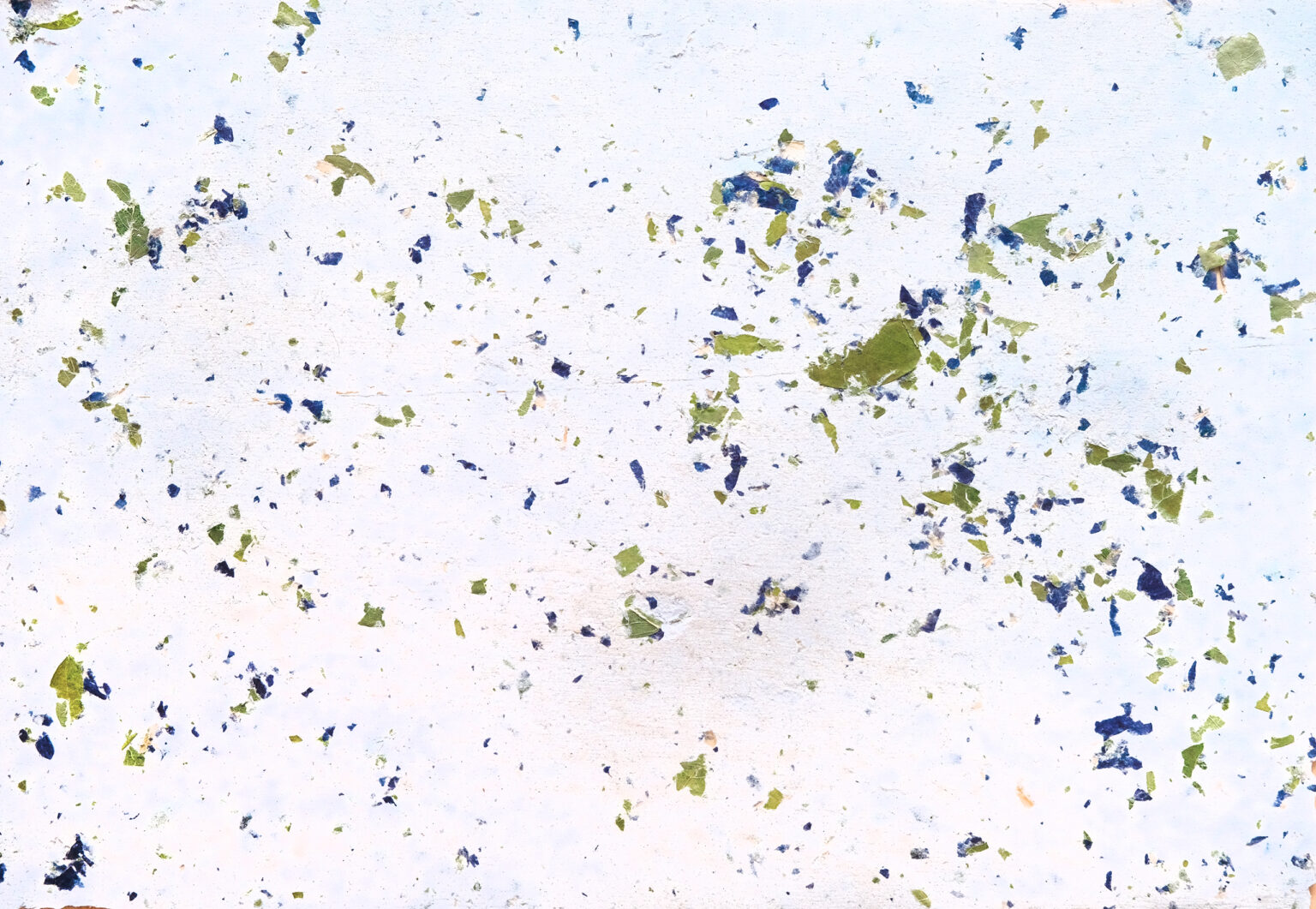

Natural Material

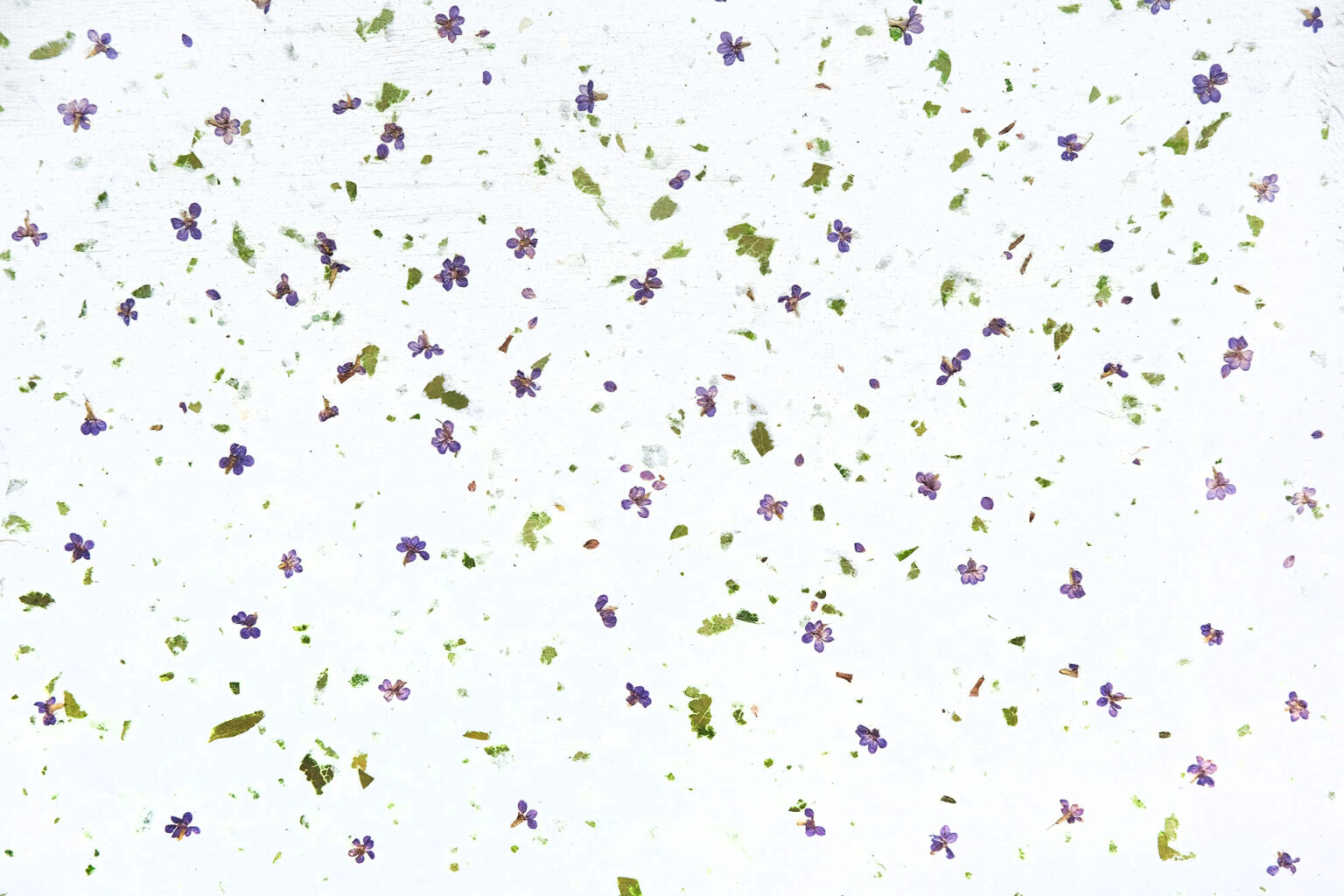

Natural Materials (Leaves)

1. Leaves with less moisture: These leaves feel like “paper,” but not waxy (too hard to incorporate into the paper) and do not easily rot, even in hot weather.

2. Retain vibrant green color: Most leaves turn yellow after drying, but some leaves, like sunflower leaves and butterfly pea leaves, can retain their original green color.

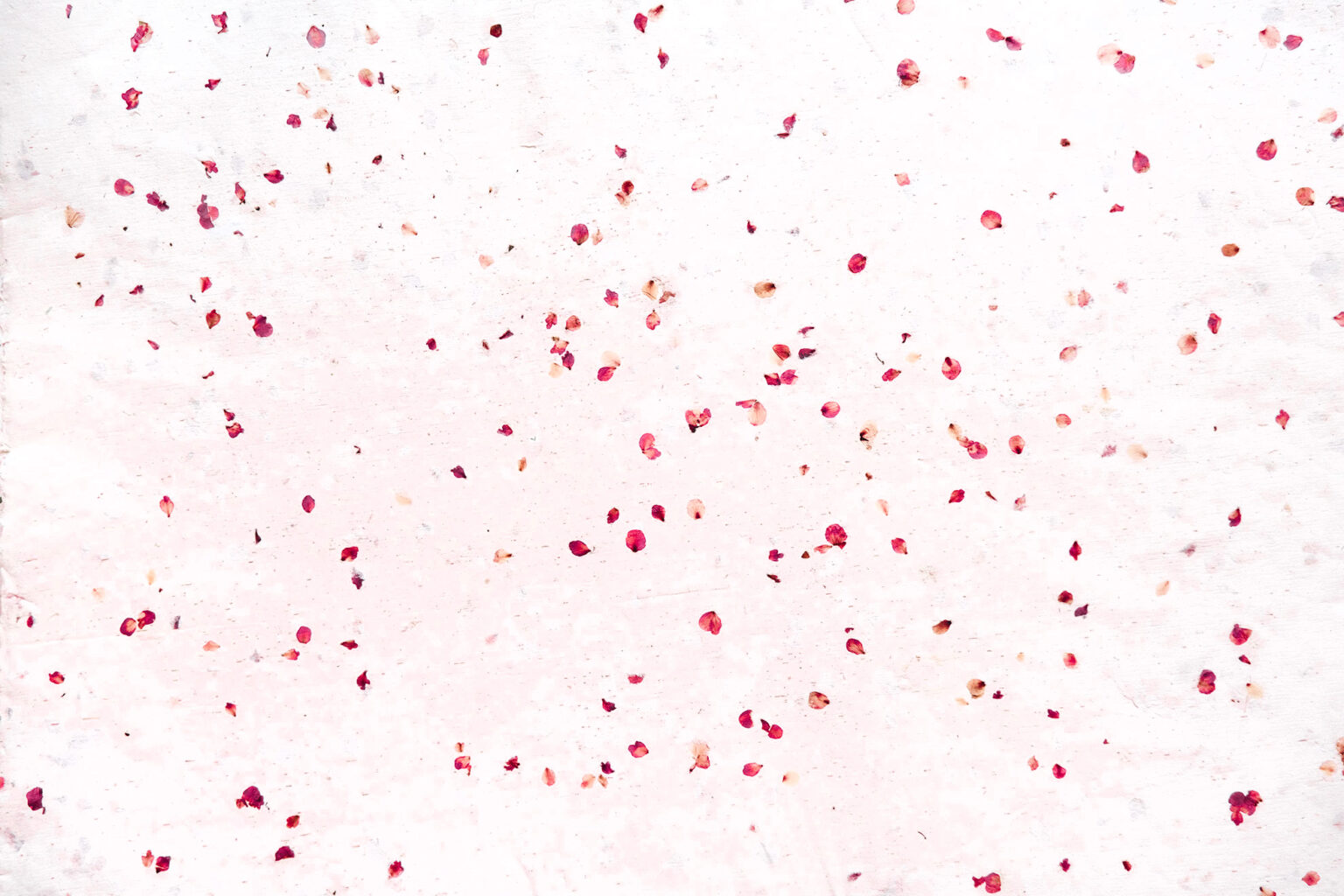

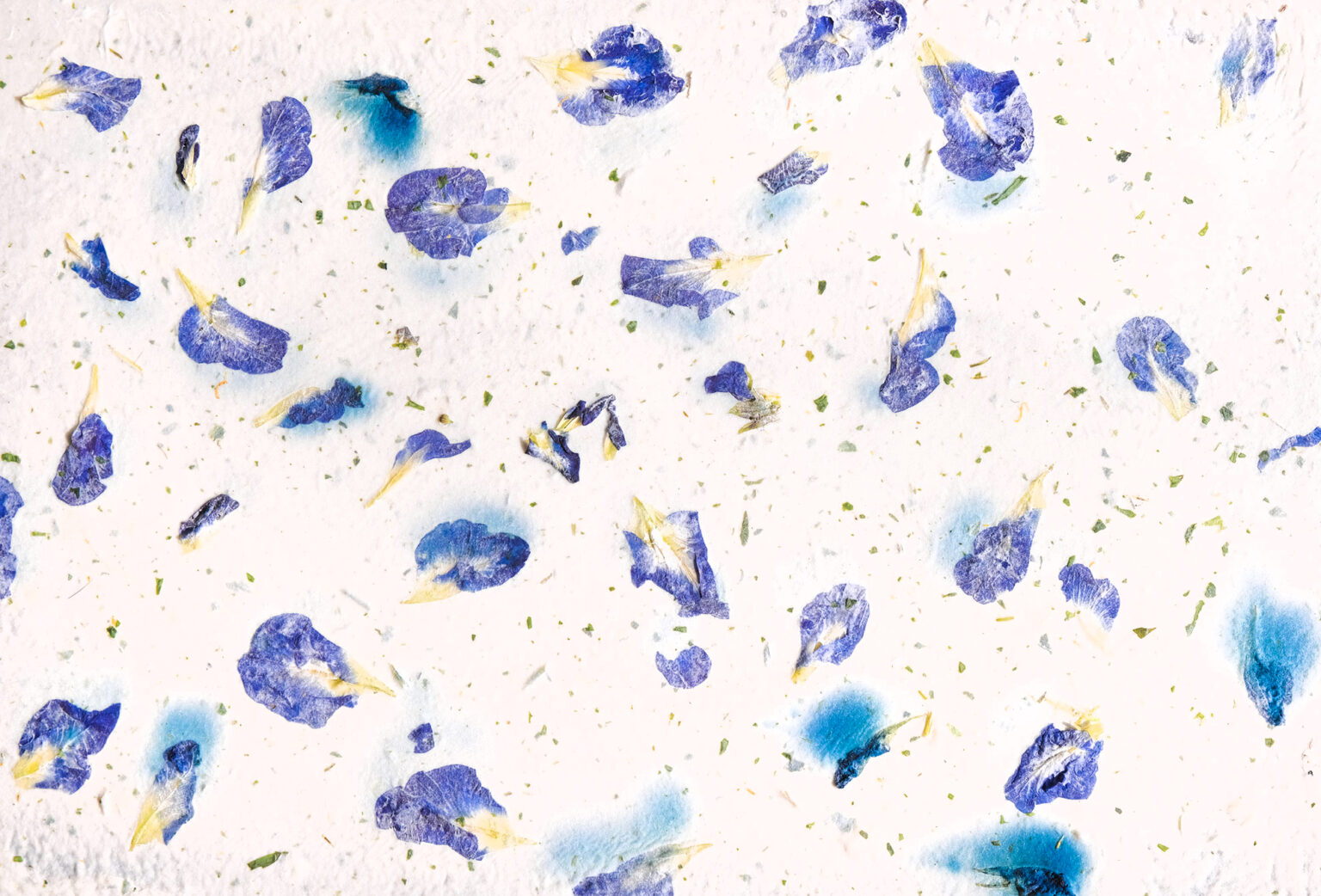

Natural Materials (Flowers)

1. Flowers with less moisture in their petals: These petals have a thin paper-like texture, making them less prone to decay and better suited for incorporation into the paper.

2. Retain bright colors: Flowers suitable for dried flower arrangements in the market are ideal, as they retain their original colors even after drying.

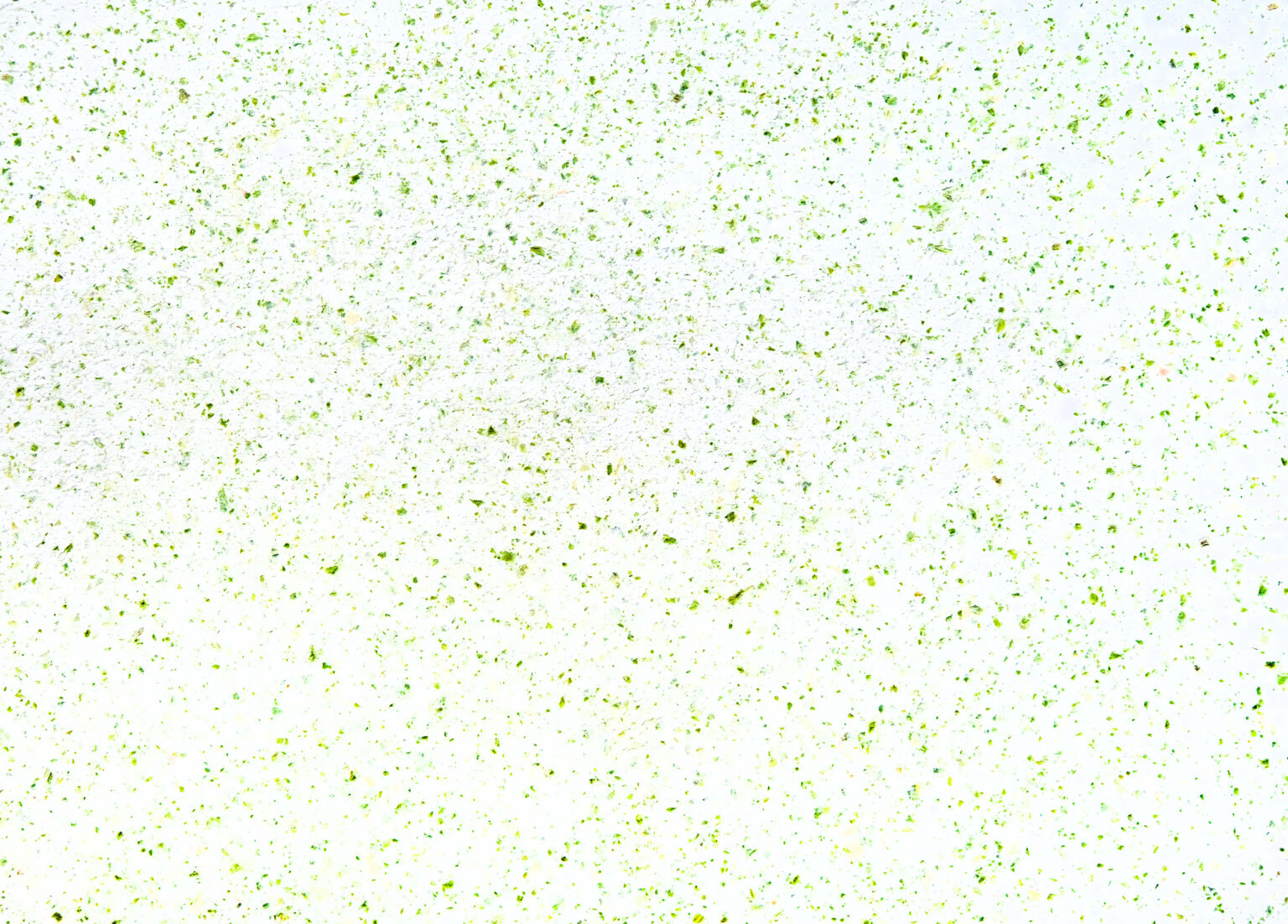

Natural Materials (Fibers)

One significant characteristic of handmade paper is the “handmade feel,” so plants with a strong fiber texture are suitable for highlighting this texture (e.g., straw, any weeds, thatch, grass, banana leaves, tea leaves, etc.).

How to Prevent Paper from Deteriorating and Decaying?

During my university graduation project, I used handmade paper as the main medium, and I practically used anything to make paper. Some of the materials produced unforgettable odors when they rotted.

1. Plants with Excessive Moisture

I tried using celery, cilantro, basil, and cruciferous vegetables (cauliflower, cabbage) to combine their fibers and texture with the paper. However, the texture didn’t retain, and instead, it ended up with an odor similar to kitchen waste . This happened because these plants contain a lot of moisture, and the paper hadn’t dried yet, causing them to decay faster (even under sunny conditions, meaning they were not suitable for making paper).

2. Weather

In humid weather, the paper not only becomes difficult to tear, but it also dries too slowly, resulting in the plants being trapped in the damp and moist pulp. On the other hand, if the sun is strong enough, the paper dries quickly and acts like a sponge to rapidly absorb the moisture from the plants, preventing them from rotting before they can be fully incorporated into the paper.

3. Drying Paper with Wooden Boards

I tried using fabric, acrylic boards, and wooden boards to dry the paper. Wooden boards, with their capillary pores, proved to be the best in absorbing moisture and releasing it quickly. This helped the plants dry faster and reduced the chance of them rotting during the drying process.

How to Prevent Paper from Deteriorating and Decaying?

1. Ubiquitous Moisture:

Both dry plants and paper are organic materials, and they are prone to quick deterioration in environments with significant humidity changes. Excessive moisture can lead to mold growth and water damage. The best approach is to seal the paper in plastic bags and periodically include desiccants inside to maintain dry conditions.

2. Ultraviolet Radiation:

Store paper in well-ventilated and cool areas, avoiding direct exposure to sunlight. Sunlight can cause paper to suffer from light-induced damage and discoloration, while plants may become brittle and eventually turn into powder due to prolonged exposure to UV radiation.

3. Insect Prevention:

For finished paper, consider the “cold storage insect extermination” method, where the paper is packed in plastic bags with most of the air removed and then sealed. Place the bag in the refrigerator for ten days to kill any insects. (This method is used after the paper is completed.)

Alternatively, during the papermaking process, adopt the “high-temperature insect extermination” method. Boil the paper pulp along with the plant material to sterilize and eliminate insects. Fresh plants may contain some insect eggs on their surface. (Boiling may sacrifice the original color of the plant materia

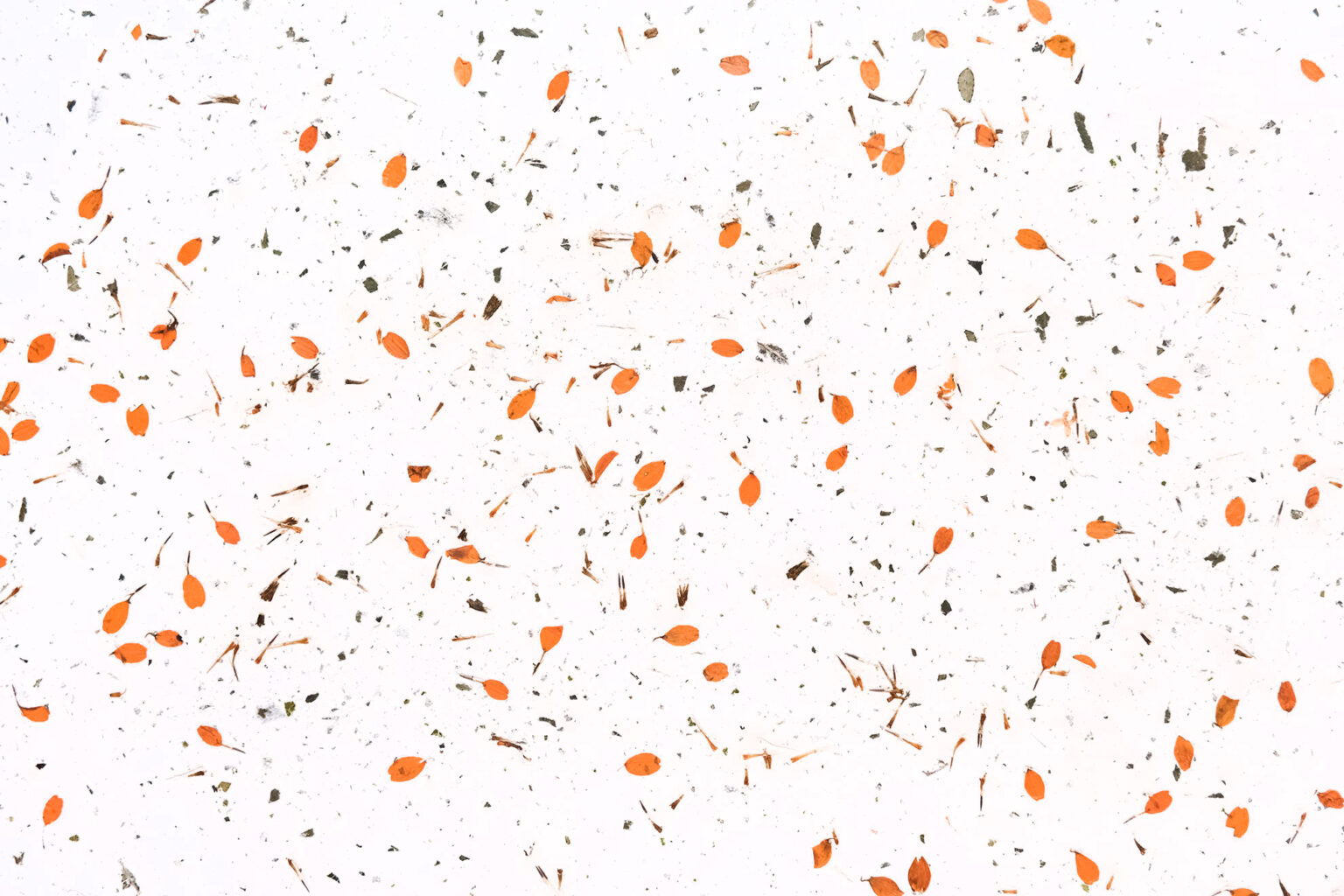

Natural Materials

The materials for making handmade paper come from Chinese Medicines, farmland, and nature. Some of them are from the fruit, spice and herbs that we use and eat daily.

Dried Flowers And Spice

Butterfly Pea | Rose | Tea Stalk | Japanese black

rice tea | fennel | Coffee | Guizotia abyssinica

Fruits And Seeds

Roselle | Butterfly pea flower | Tangerine

| Lemon leaf | Citronella | tea

Flowers And Spice

Kapok | Citronella | Melaleuca | Wormwood |

Basil | Osmanthus | Mint | Oriental Hawksbeard

Chinese Medicines

Chrysanthemum | Rose | Cinnamon |

Lavender | Rosemary | Mugwort | Coreopsis

tinctoria | Rice

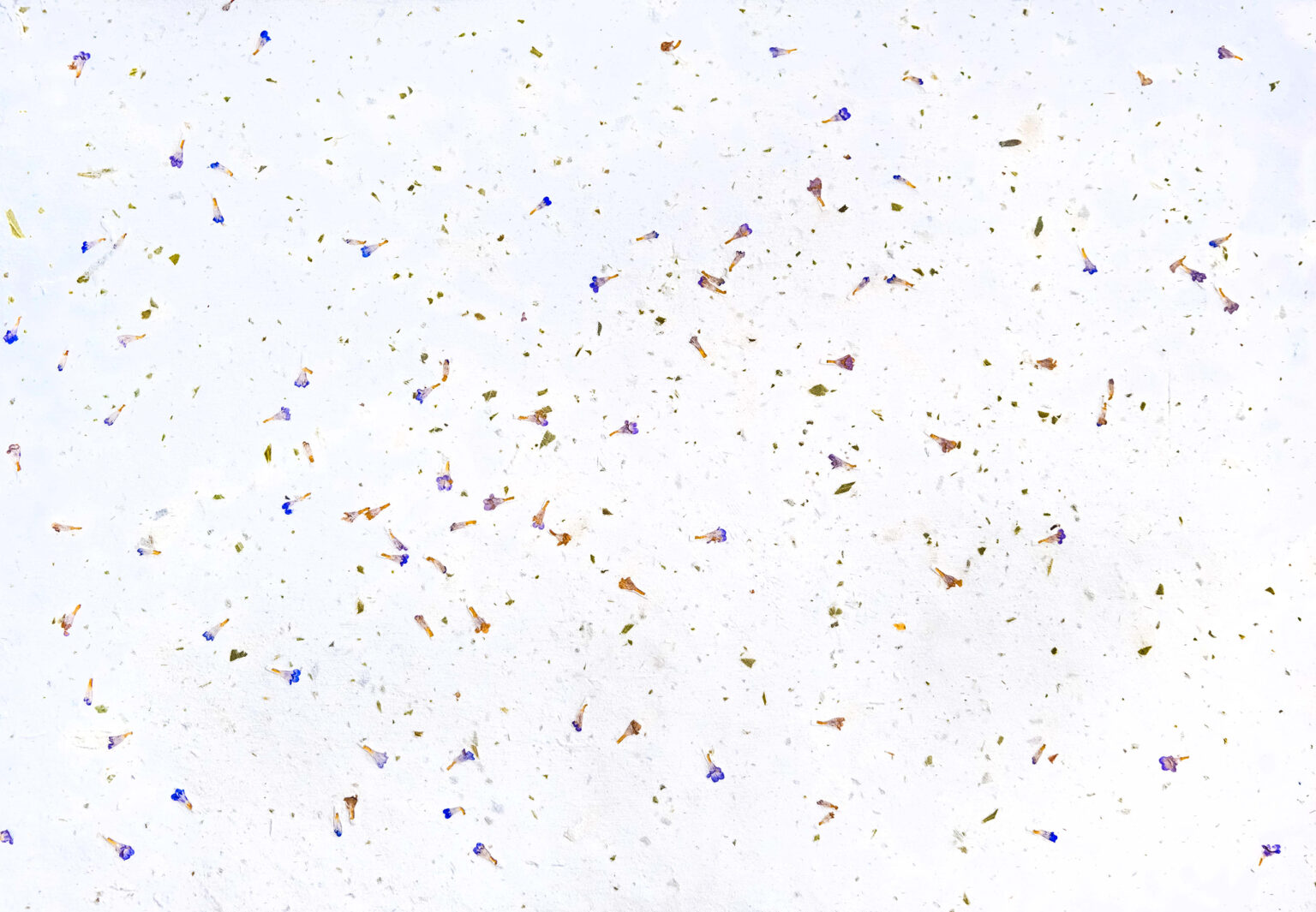

Flowers And Teas

Black Tea, Roses, Camphorwood,

Paper Flower

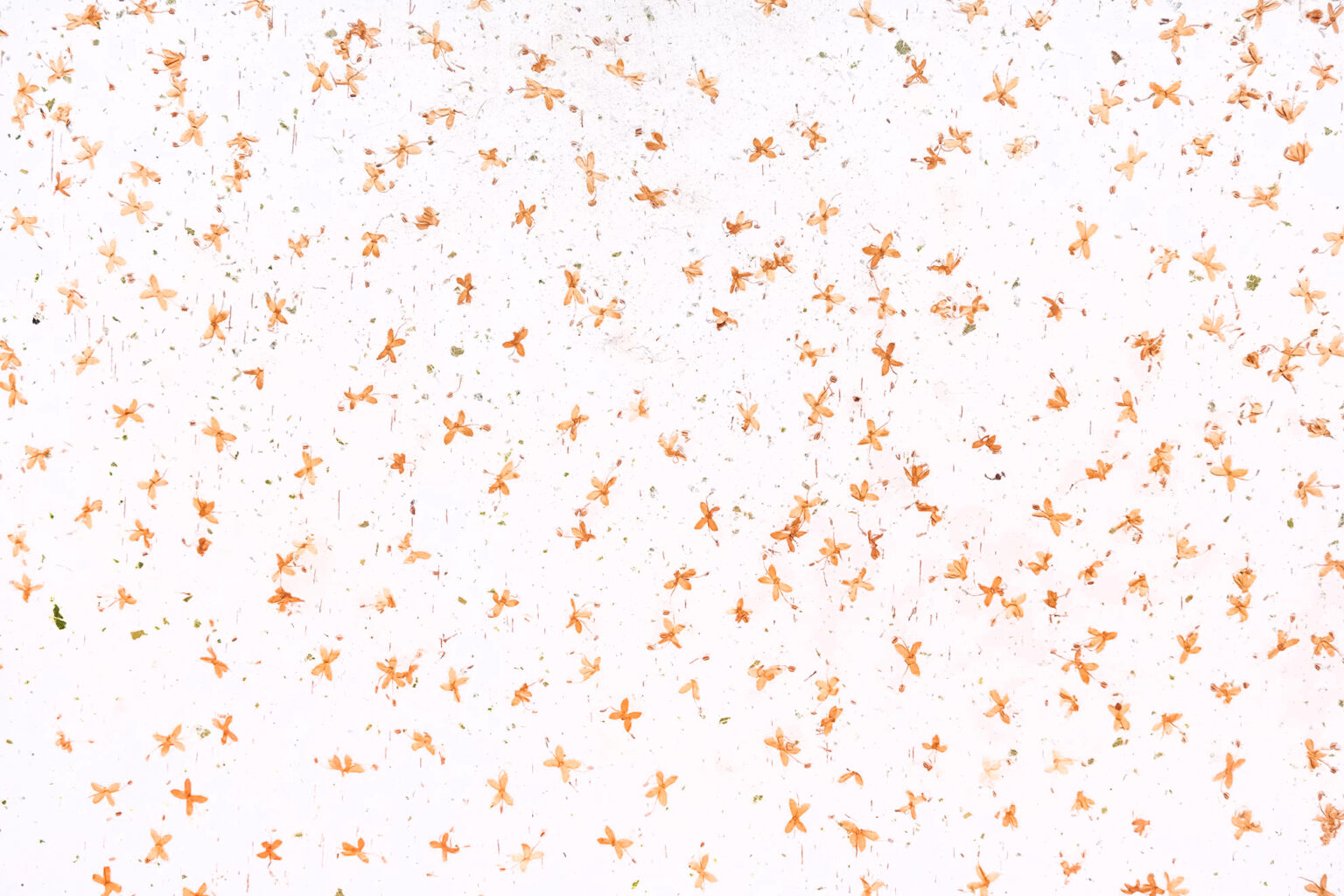

Flowers

Cuphea Hyssopifolia, Sandpaper Vine,

Limonium Sinuatum

Fresh Spice

Mountain Marigold, Pandanus Amaryllifolius,

Lemon Balm, Chamomile, Basil, Basili

Paper Pulp

Recycled Paper, Cotton, Thick Cardboard,

Wood Pulp, Newspaper

Flowers And Fresh Herbs

Rosemery, Laverder, Ligustrum Sinense Lour,

Lavende Stoechade

Fresh Herbs

Fresh Herbs

Coleus Amboinicus, Mint, Rosemary, Melaleuca, Garlic, Perilla, Shell Ginger, Basil, Red-Veined Dock

Cooking Process

Sunflower

Ornamentation

Raw Materials For Wood Pulp

Ligustrum Punctifolium, Paper Mulberry, Gampi Tree, Pteroceltis Tatarinowii, Bamboo Straw and Water Bamboo

''These types of materials are commonly used to make the basic ingredients for making paper''

Tools For Making Paper

Handmade different size of mould and deckle

Each handmade piece of paper is unique. When you stir your vat of pulp, the ingredients float on the water in different positions, so when we dip the mould and deckle to the bottom of the vat and scoop up, the patterns will become completely unique.

Making Procedure

Collect Ingredients

Collecting the ingredients that we need from surrounding.

Cook The Ingredients

Simmering various parts of the plant, especially the flower, is the important because the stamens, pistils, corolla, and petals will release a scent of nature. The softened fibers of stems and leaves can be mixed with the pulp to produce different textures.

Layout

After cooking, chlorophyll is released into the pulp, so papers become a slight green naturally. Pulling some sheet. After sheet formation, putting some petal for decoration.

Drying

After transferring a wet sheet from a mould to a flat and giving a hard pressing, let it dry and pull it off.

Puli Paper Factory

Investigation Of Making papers

Ingredient Of Pulp

The bark fibers of mulberry are soft and delicate and the fibers of paper mulberry are tough. The pulp made from the bark of both is of extremely high quality.

Tool For Making Paper

They offer basic tools for people to learn and play.

Craftsmen

Malabar chestnut roots are sliced, soaked, and pressed to form a natural suspending agent for papermaking.

Craftsmen

The function as a suspending agent is to slow down the speed of water flow to facilitate the control of paper thickness.

Paper has been a medium to carry cultures, history, civilizations, poetry and words of ancient and modern China and foreign countries, and emotions and desires of human beings.

Handmade Paper Show

With Different Patterns, Colors, Texture, Scent And Plants